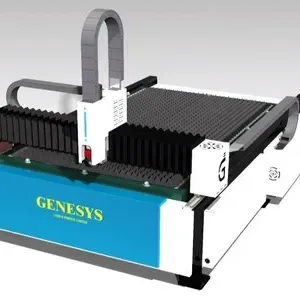

Product Description

A single blade block cutting machine is a specialized piece of equipment used in the stone processing industry, particularly in the cutting and shaping of large blocks of natural stone such as marble, granite, or other types of dimensional stone. Below is a comprehensive description of a typical single blade block cutting machine:

-

Machine Structure:

- The machine typically consists of a sturdy and stable structure, often made of steel or cast iron, to provide the necessary support and rigidity during the cutting process.

-

Blade Assembly:

- The heart of the machine is the cutting blade assembly. In a single blade block cutting machine, there is only one blade responsible for cutting through the stone block. The blade is usually made of high-quality, durable material such as diamond segments embedded in a metal matrix, ensuring efficient and precise cutting.

-

Blade Movement Mechanism:

- The cutting blade is mounted on a motor-driven arbor or spindle, allowing for the rotation of the blade. The movement can be controlled manually or, in more advanced machines, through computerized systems for enhanced precision.

-

Cutting Process:

- The stone block is positioned on a worktable, and the cutting blade is lowered onto the block to initiate the cutting process. The blade cuts through the stone by grinding away material along the desired cutting path.

-

Adjustable Parameters:

- Single blade block cutting machines often feature adjustable parameters such as cutting depth, speed, and feed rate. These adjustments allow operators to optimize the cutting process based on the type of stone being processed and the desired outcome.

-

Control System:

- Advanced machines may be equipped with a control system that allows operators to input specific cutting parameters, monitor the cutting process, and make real-time adjustments for optimal performance.

-

Water Cooling System:

- To prevent overheating and to facilitate dust suppression, many block cutting machines are equipped with a water cooling system. Water is often directed onto the cutting blade and cutting area during operation.

-

Dust Extraction System:

- A dust extraction system is crucial for maintaining a clean and safe working environment. It helps remove the fine stone dust generated during the cutting process, enhancing visibility and preventing respiratory issues for operators.

-

Safety Features:

- Safety features are integrated into the machine design to protect operators. These may include emergency stop buttons, protective guards, and safety interlock systems that prevent the machine from operating if safety parameters are not met.

-

Worktable and Clamping System:

- The worktable typically has a clamping system to secure the stone block in place during cutting. The table may be adjustable to accommodate different block sizes.

-

Waste Management:

- The machine may incorporate features for efficient waste management, such as a conveyor system to remove cut pieces or a collection system for stone slurry.

-

Maintenance and Accessibility:

- The machine is designed to be easily accessible for maintenance purposes. Regular maintenance is essential to ensure the longevity and reliability of the equipment.